- The Role of Drones in High-Risk Work Environments

- Drone Technology Enabling Safer Inspections

- Regulatory and Ethical Considerations

- Drone Adoption and Market Growth in Manufacturing

- Best Practices for Implementing Drones in Hazardous Environments

- Drones vs. Robots: A Quick Comparison

- The Safer Future of Work

- References

In workplaces where danger is part of the daily environment—chemical plants, nuclear facilities, oil refineries, and disaster response zones—drones are becoming unsung heroes. Equipped with cutting-edge technologies like thermal cameras, gas sensors, LiDAR, and AI, drones are transforming how inspections and safety protocols are carried out.

By reducing the need for humans to physically enter high-risk areas, smart drones are saving lives, lowering costs, and reshaping the future of workplace safety.

The Role of Drones in High-Risk Work Environments

Drones, also known as unmanned aerial vehicles (UAVs), have long been used for aerial photography and military operations. But their increasing application in hazardous work environments is proving just as transformative. Dow Chemical and State Farm are just two examples of corporations now using drones to reduce their employees’ need to access dangerous heights [11].

In chemical manufacturing plants, drones are deployed to monitor for leaks, assess structural integrity, and inspect elevated equipment. Nuclear facilities, such as those in post-Fukushima Japan, have used drones to assess radiation levels and inspect damage in areas unsafe for human workers [1]. Similarly, drones have played a key role in emergency response zones, surveying collapsed buildings after earthquakes or identifying heat sources in forest fires [2].

Because they can fly, hover, and maneuver through narrow or dangerous spaces, drones dramatically reduce the need for human personnel in potentially fatal environments. Their use is especially prevalent in confined spaces like reactors, storage tanks, and offshore rigs, where risks include toxic fumes, radiation, fire, and physical collapse.

Drone Technology Enabling Safer Inspections

Smart drones are not just flying cameras; they are multi-sensor intelligence platforms capable of real-time environmental analysis.

Thermal Imaging

One of the most widely used drone technologies in hazardous workplaces is thermal imaging, which enables the detection of heat anomalies. For example, drones equipped with FLIR thermal sensors can identify overheating motors or circuitry in industrial facilities long before failure occurs.

These capabilities have also been used in firefighting scenarios, where drones detect hotspots or locate survivors based on body heat. In a 2023 study, drones equipped with thermal cameras helped identify ignition sources and monitor structural heat stress during wildfires [3].

Gas Sensors

Drones with gas detection sensors are vital in chemical, oil and gas workplaces. They can detect hazardous gases such as methane, carbon monoxide, sulfur dioxide, or volatile organic compounds (VOCs). Rather than risking human exposure, drones carry sensors like electrochemical detectors or TDLAS (Tunable Diode Laser Absorption Spectroscopy) modules to assess gas concentrations in real time [4].

This application is crucial in confined space inspections for any industry, including agriculture, utilities, and public works, where gas accumulation can be deadly.

LiDAR (Light Detection and Ranging)

LiDAR-equipped drones use laser pulses to generate high-resolution 3D maps of facilities. These are invaluable in low-light or smoky conditions, and particularly in structural inspections of bridges, pipelines, or underground mines.

A study on mine safety showed how LiDAR drones are being used to map underground tunnels, reducing the need for human presence in areas prone to collapse or toxic exposure [5].

AI and Autonomous Navigation

What sets modern drones apart is their ability to navigate autonomously using AI and onboard computing. Through machine learning algorithms, computer vision, and simultaneous localization and mapping (SLAM), drones can identify hazards like cracks or heat leaks and plan inspection routes without human intervention.

AI-driven systems are now also used for predictive maintenance. These models analyze inspection data to predict future failures, allowing companies to address risks before they escalate [6].

Regulatory and Ethical Considerations

As drone deployment becomes more advanced and widespread, regulatory and ethical frameworks are evolving to ensure safety, compliance, and privacy.

FAA and OSHA Guidelines

- 14 CFR Part 107 governs the commercial operation of small, unmanned aircraft systems (sUAS) under 55 pounds. It mandates Remote Pilot Certification, adherence to visual line-of-sight (VLOS) requirements, altitude restrictions (generally up to 400 feet above ground level), and operational limitations regarding flying over people or at night—unless a waiver is obtained.

- 14 CFR Part 89 (Remote Identification), effective since September 2023, requires most drones operating in U.S. airspace to broadcast identification and location information during flight. This ensures traceability, particularly in sensitive or high-risk environments.

- 14 CFR Part 91, Subpart E covers special flight operations, allowing operators to apply for waivers or exemptions in scenarios such as flying in controlled or restricted airspace (e.g., disaster zones, near airports, or national security areas).

- 49 CFR Part 175, issued by the Department of Transportation (DOT), regulates the carriage of hazardous materials by air. It prohibits drones from transporting hazardous substances unless specific exemptions or approvals are granted, which is critical when operating in chemical or radiological hazard zones.

These federal frameworks, enforced by the Federal Aviation Administration (FAA) and aligned with OSHA workplace safety standards, are essential for ensuring the safe and compliant integration of drones into industrial and emergency operations [7].

Ethical Concerns

Drones collecting environmental or visual data often raise privacy concerns, particularly if their footage inadvertently includes nearby homes or individuals. Additionally, companies must ensure data security and responsible use of surveillance footage and sensor data.

Transparency about drone usage, informed consent in monitored areas, and ethical data practices are increasingly expected by stakeholders and regulators alike.

Training and Oversight

Just like operating a forklift or electrical system, drone operators must be certified, trained, and follow site-specific safety protocols. Companies should implement internal policies and procedures to manage compliance and ensure operators understand both the capabilities and limitations of drone systems.

Drone Adoption and Market Growth in Manufacturing

The use of drones is surging in industrial sectors as companies seek safer, more efficient alternatives to manual inspections.

Market Outlook

The industrial drone market is experiencing rapid growth, driven by the increasing demand for automation, real-time analytics, and improved workplace safety. According to recent industry projections, the global industrial drone market is expected to grow from $17.8 billion in 2023 to over $57.9 billion by 2030, fueled by their expanding role in sectors like manufacturing, logistics, construction, and energy [8].

In manufacturing, more than 43% of large North American firms already utilize drones for facility inspections, compliance auditing, and non-destructive testing—a figure expected to rise to over 60% by 2026 [9]. In high-risk sectors such as oil and gas, drones are widely deployed for pipeline surveillance, gas leak detection, and flare stack monitoring. This trend reflects a broader shift toward Industry 4.0 strategies, particularly in Asia-Pacific, where smart factory initiatives are accelerating drone integration [10].

As automation and safety become central to industrial operations, drones are increasingly viewed not just as surveillance tools but as intelligent, decision-support systems. Their ability to deliver real-time insights while minimizing human exposure is reshaping how workplaces approach inspection, maintenance, and risk management.

For instance, manufacturing facilities are increasingly adopting drones for non-destructive testing, leak detection, and plant mapping, aligning with broader Industry 4.0 strategies and workplace automation goals [8].

Best Practices for Implementing Drones in Hazardous Environments

To fully realize the benefits of drones in safety-critical operations, companies should adopt a set of best practices.

Risk Assessment & Planning

Before deployment, assess environmental risks (wind, gas emissions, electromagnetic interference), mission objectives, and legal constraints. Involve safety teams and drone specialists early in the planning phase.

Hardware Selection

Match drone capabilities to operational needs:

- Thermal sensors for heat detection

- Gas detectors for chemical exposure

- LiDAR for mapping and inspection

- Flight endurance suitable for mission length

Certification & Training

Ensure all drone operators are certified under FAA Part 107 and trained in emergency procedures and site-specific hazards.

Data Management

Establish a robust system for handling drone-captured data. This includes secure storage, encryption, retention policies, and AI-assisted analysis.

Maintenance & Compliance

Schedule routine maintenance, software updates, and calibration of sensors. Periodically review operations for compliance with evolving FAA, OSHA, and state-level drone laws.

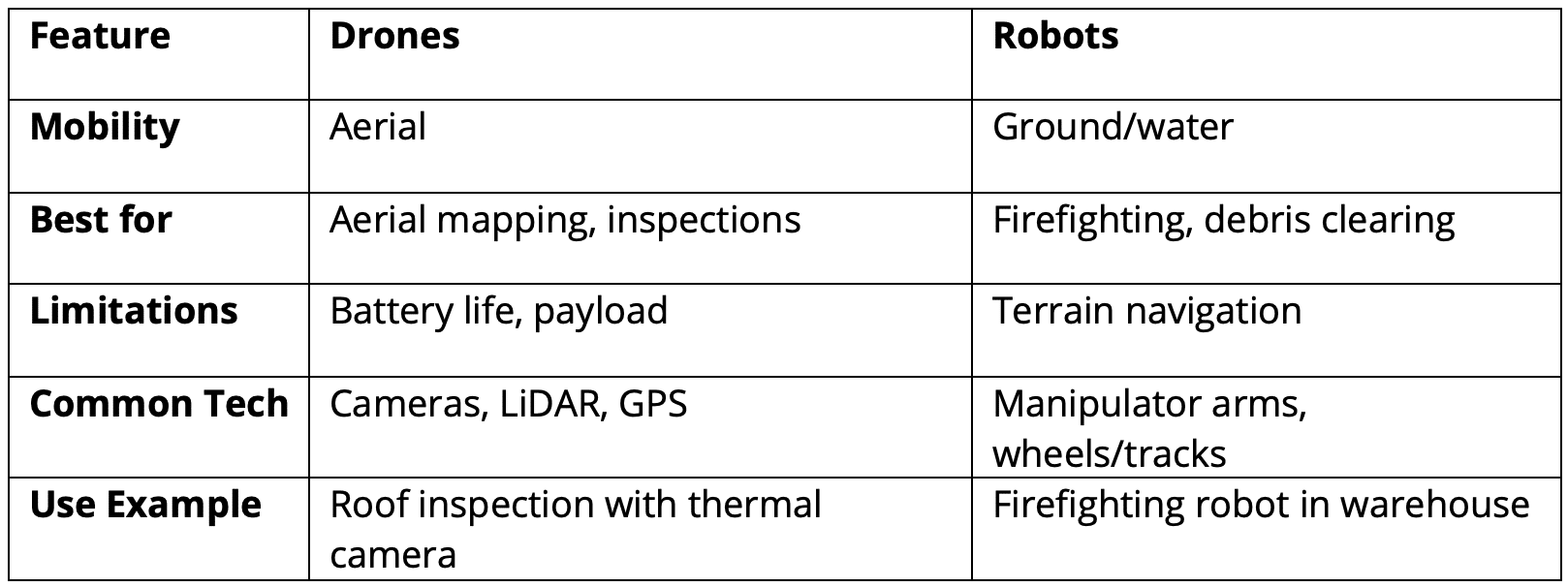

Drones vs. Robots: A Quick Comparison

While both drones and robots are revolutionizing hazardous work, they serve distinct purposes.

The Safer Future of Work

Smart drones are more than futuristic gadgets; they are pivotal tools in modern workplace safety. By integrating AI, thermal imaging, LiDAR, and remote sensing, they drastically reduce the need for human presence in the world’s most dangerous environments. As regulations evolve and adoption accelerates, drones are poised to become essential safety agents across manufacturing, energy, and emergency response sectors.

For workplaces committed to protecting human life while embracing innovation, drones offer a powerful path forward.

References

1. Smith, N. T., Y. Yamashiki, P. G. Martin, and S. Kwong. “3D UAV Radiation Mapping for Assessing Contaminant Distribution and Mobility.” International Journal of Applied Earth Observation and Geoinformation (2022). https://www.sciencedirect.com/science/article/pii/S0303243416300733

2. Alsammak, Ismail L. H., Mahmoud A. Mahmoud, Hairulnizam Aris, and others. “Forest Fire Mitigation Using UAV Swarms: A Review of AI-Based Path Planning and Detection Techniques.” Drones 6, no. 2 (2022): 80. https://www.mdpi.com/1999-4907/13/5/811

3. Perikleous, Demetrios, George Koustas, Sotiris Velanas, Konstantina Margariti, Diego Gonzalez-Aguilera, and Theodoros Papatheodorou. “A Novel Drone Design Based on a Reconfigurable Unmanned Aerial Vehicle for Wildfire Management.” Drones 8, no. 5 (2024): 203. https://www.mdpi.com/2504-446X/8/5/203

4. Burgués, Jordi, and Santiago Marco. “Environmental Chemical Sensing Using Small Drones: A Review.” Science of the Total Environment 748 (2020): 141172. https://www.sciencedirect.com/science/article/abs/pii/S004896972034701X

5. Onifade, Moshood, Tawanda Zvarivadza, and John Adetunji Adebisi. “Towards Application of Positioning Systems in the Mining Industry.” International Journal of Mining and Mineral Engineering, May 29, 2024, 15–48. https://www.inderscienceonline.com/doi/abs/10.1504/IJMME.2024.138723

6. Igwenagu, Udochukwu Ikechukwu, Rahul Debnath, Ahmed Abdelmoamen Ahmed, and Md Jobair Bin Alam. “An Integrated Approach for Earth Infrastructure Monitoring Using UAV and ERI: A Systematic Review.” Drones 9, no. 3 (2025): 225. https://www.mdpi.com/2504-446X/9/3/225

7. Federal Aviation Administration. “Unmanned Aircraft Systems (UAS).” Federal Aviation Administration, last modified 2023. https://www.faa.gov/uas

8. Askerbekov, Dauren, José Arturo Garza-Reyes, Ranjit Roy Ghatak, Rohit Joshi, Jayakrishna Kandasamy, and Daniel Luiz de Mattos Nascimento. “Embracing Drones and the Internet of Drones Systems in Manufacturing: An Exploration of Obstacles.” Technology in Society 76 (2024): 102648. https://www.sciencedirect.com/science/article/pii/S0160791X24001969

9. Nwaogu, Janet Mayowa, Yang Yang, Albert P. C. Chan, and Hung-lin Chi. “Application of Drones in the Architecture, Engineering, and Construction (AEC) Industry.” Automation in Construction 152 (2023): 104827. https://www.sciencedirect.com/science/article/abs/pii/S0926580523000870

10. Kuljanin, Jovana, Tanja Zivojinović, Nataša Bojković, and Cristina Barrado. “Drone Technology in Industry 4.0: Challenges and Obstacles in Urban Environments.” In Industry 4.0 and Beyond, edited by M. Novak and D. Subic. CRC Press, 2024. https://www.taylorfrancis.com/chapters/edit/10.1201/9781003511298-10/drone-technology-industry-4-0-jovana-kuljanin-tanja-zivojinovi%C4%87-natasa-bojkovic-cristina-barrado

11. Fillmer, Scott “Why Drones are Essential for Improving Workplace Safety” The Drone Life The Sky is no Longer the Limit. February 24, 2023. https://thedronelifenj.com/drones-workplace-safety/